Factory Material Transfer Wagon

Factory Material Transfer Wagon

The drive wheels and bearing wheels of the factory material transfer wagon can be made of high-strength polyurethane rubber solid tires, free from the dependence on the ground track, without damaging the infrastructure, can walk freely on the ground, randomly turn from the ground and space, and can walk at any time and the change of route is very suitable for on-site operation on fixed lines.

1. The safety performance requirements of trackless flat cars are high: for most heavy workpieces, the safety of personnel and items must be ensured during transportation, and accidents such as bumps or dumping must not occur.

2. Heavy-load capacity of factory material transfer wagon: heavy-duty workpieces are heavier and some can weigh hundreds of tons.

3. The mould of trackless flat car has large elasticity, large volume, and large space during movement.

4. Low table of factory material transfer vehicle: the height of the compression molding machine is limited, and the mold transportation height cannot be too high.

5. The trolley-free flat car is easy to operate: the mold die is not just the die, it will be replaced by many dies.

6. The operation of the trackless flat car is not limited: the mold occupies more workshop space, and the transportation equipment should be able to transfer the mold anytime and anywhere.

7. Trackless flat car protects the floor of the workshop: Since the mold is generally heavy and the pressure of each wheel is relatively heavy, the wheel material is very strong and will not cause damage to the ground.

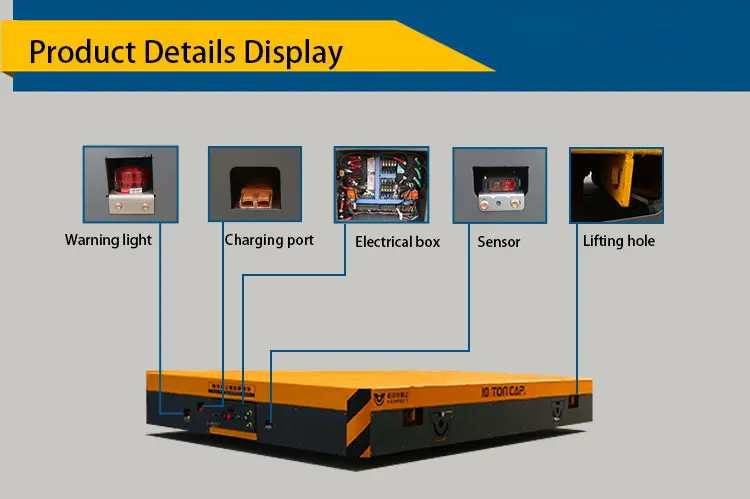

Detailed Image Of transfer cart

Processing Line Of transfer cart

Functions & Advantages Of transfer cart

Extreme Environment Resistance: Built to withstand high temperatures and prevent explosions, ensuring reliable operation in harsh or hazardous workspaces.

Flexible Power Solutions: Supports multiple power options-battery, low-voltage rail, cable drum, and trailing cable-to adapt seamlessly to diverse workshop layouts and operational needs.

Easy Handling & Shipment: Equipped with integrated lifting holes, simplifying transportation, loading, and installation of the cart itself.

Robust Performance: Delivers stable startup, powerful initial torque, and an extended service life, maintaining consistent operation even under heavy-duty conditions.

Versatile Track Compatibility: Navigates smoothly on C-shaped, S-shaped, and L-shaped rails, accommodating complex path requirements within production facilities.

Unlimited Travel Range: Eliminates distance constraints, enabling continuous transportation across the entire span of your operational area.

Safe & Intuitive Operation: Prioritizes operator safety and ease of use, minimizing complexity and reducing training time.

High Operational Frequency: Constructed to handle frequent, repeated use, making it ideal for high-throughput production lines requiring non-stop material movement.

Packaging & Shipping

Certifications

Hot Tags: factory material transfer wagon, China, manufacturers, suppliers, factory, customized, made in China, Electric Mold Transfer Cart, Motorized Mould Transport Cart, Factory Material Transfer Wagon, Trackless Electric Flat Car, Mold Transport Flat Rail Vehicle, Mold Transport Cart

Send Inquiry